Time :2026-01-28 Source: 本站原创 Views:36

The extreme performance demands of outdoor and workwear mean zero-carbon transition must start with breakthrough raw material innovation. We embed SORONA’s “plant-based innovation + full-life-cycle carbon reduction” philosophy deep into our raw material system, shattering the myth that “sustainability compromises performance” and making every fiber green yet robust. Currently, this innovative material system has been applied to our new outdoor apparel and workwear lines, translating green performance from the material stage to real-world use.

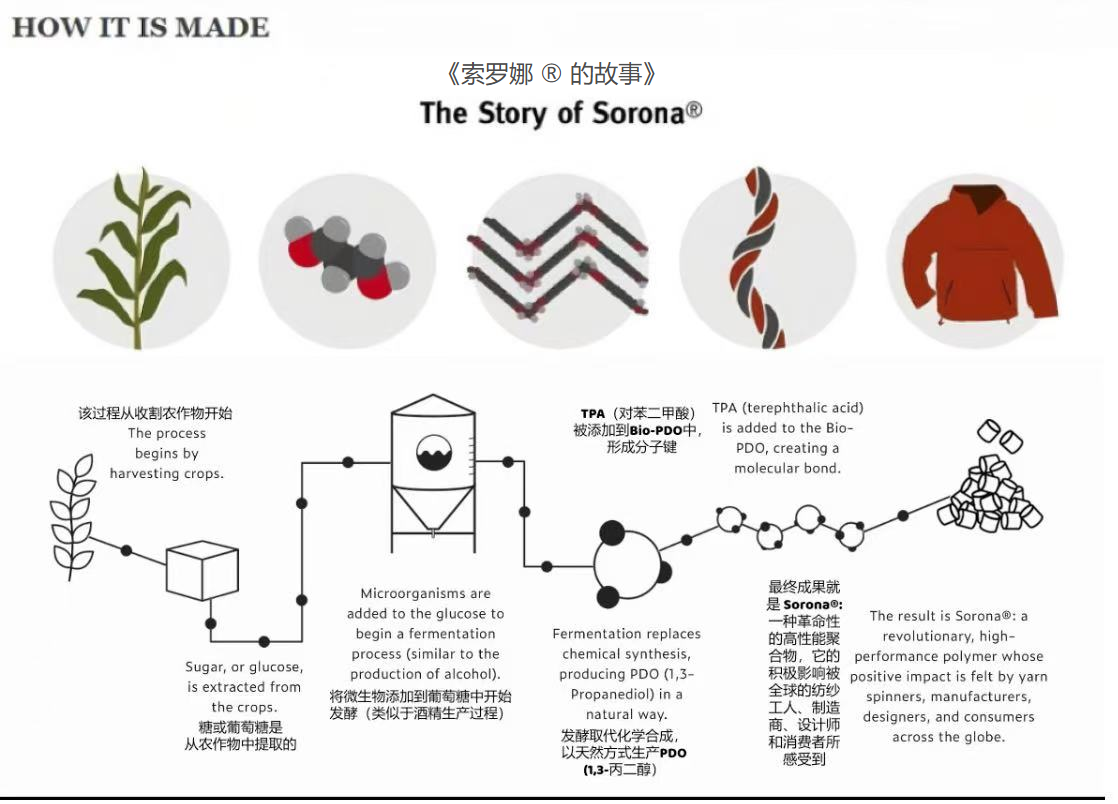

In our core outdoor apparel line, we innovate with SORONA/recycled PET composite fabric — SORONA fibers are derived from corn starch fermentation. With 37% plant-based content, their production saves 44% more energy and cuts greenhouse gas emissions by 170% compared to traditional nylon 6. For every 1,000 outdoor jackets made with this composite fabric, 28,000 waste plastic bottles are recycled, while raw material carbon emissions are further reduced by 22%. Our new outdoor jackets fully adopt this composite fabric. Tests show it withstands 30,000 rub cycles intact, retains permanent elastic recovery with less than 2% deformation after stretching, and boasts 40% higher abrasion resistance than pure recycled PET fabric. It perfectly meets the tear challenges of complex outdoor environments, delivering more reliable protection for outdoor enthusiasts.

To meet the multi-functional needs of workwear, we’ve built a recycling system of “retired workwear + SORONA”: old protective clothing from the construction industry is disassembled and re-spun with SORONA fibers, retaining core anti-stab and anti-static properties while leveraging SORONA's UV resistance and easy-care features.This recycled system has been applied to our new workwear line, achieving a 5-level sun protection rating, easy wipe-clean of oil stains, and a 1.5x longer service life than traditional workwear. Notably, this composite recycled fabric can directly enter the regular polyester recycling stream, solving the industry pain point of difficult recycling for traditional spandex-blended workwear and truly achieving a resource closed loop.

In the dyeing process, leveraging SORONA fibers’ excellent dye adaptability, we use natural plant extracts like pine needles and gallnuts for coloration. This dyeing solution is applied to our new products, meeting requirements for acid-alkali and sun-resistant color fastness, while cutting water consumption by 60% and wastewater treatment costs by 40% in dyeing. It ensures our new products adhere to green standards across the entire chain from raw materials to finished goods.

Previous: 2026 OEKO-TEX® STANDARD 100 Certification Renewed Successfully

Next: None